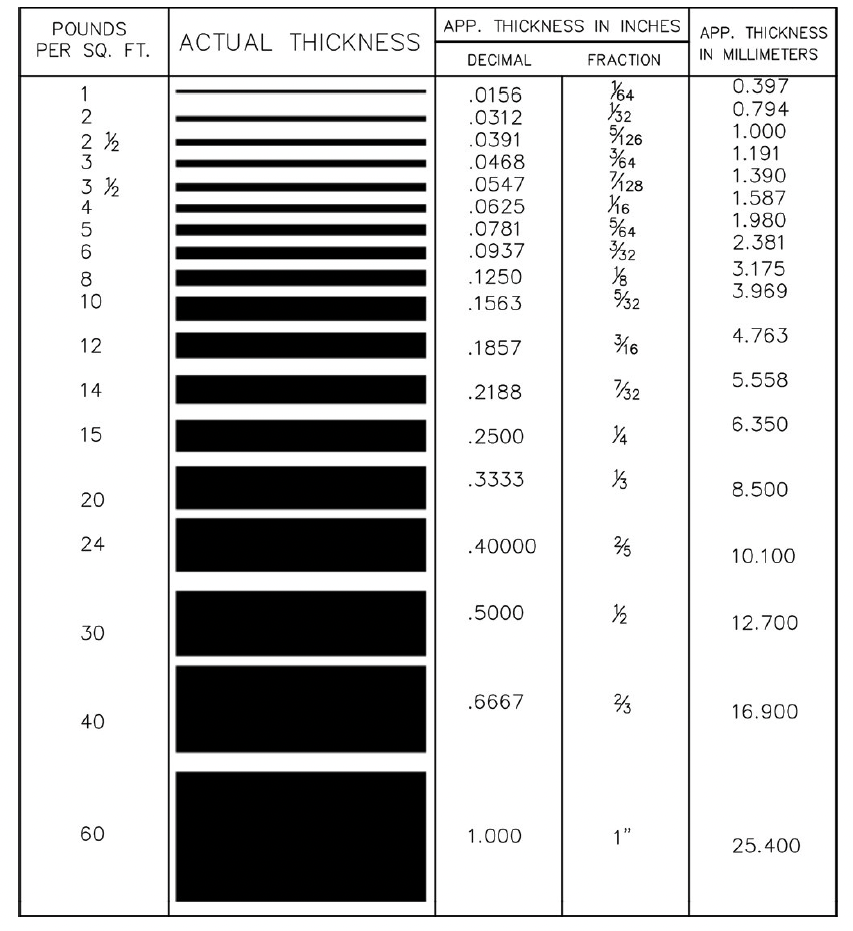

Gypsum drywall panels are pressure laminated with permanent adhesive to unpierced sheet lead and arranged to provide effective lead shielding through all joints. Gypsum board panels are secured to studs with drywall screws. Leaded drywall panels will be greater than or equal to the attenuation level specified by the physicist. Leaded dry wall sizes are typically on 5/8” thick or ½” thick 4’ x 8’, 4’x9’ or 4’x10’ sheetrock gypsum wallboard with 49” wide sheet lead rolled up to 7’ or 8’ high. Some typical lead thicknesses are:

- 1/32” (2 lb. per sq. ft.)

- 1/16” (4 lb. per sq. ft.)

- 3/32” (6 lb. per sq. ft.)

- 1/8” (8 lb. per sq. ft.)

In addition to regular drywall, our supplier can apply lead to mold and moisture resistant gypsum wallboard, impact and abuse resistant gypsum wallboard and Type X fire rated wallboard. All drywall products are covered under the ASTM C 1396 gypsum board standard specification. Regular drywall is naturally fire resistant due to the presence of gypsum in the core, but it is not fire rated. Type X drywall includes special core additives that allow it to be used in fire rated designs and usually comes in 5/8” thickness. We can also can apply lead to plywood. Please reach out to us to learn more about Lead Lined Plywood.

Standard Installation:

- Place leaded side of drywall against studs.

- Drill pilot holes for screws to prevent deformation of lead.

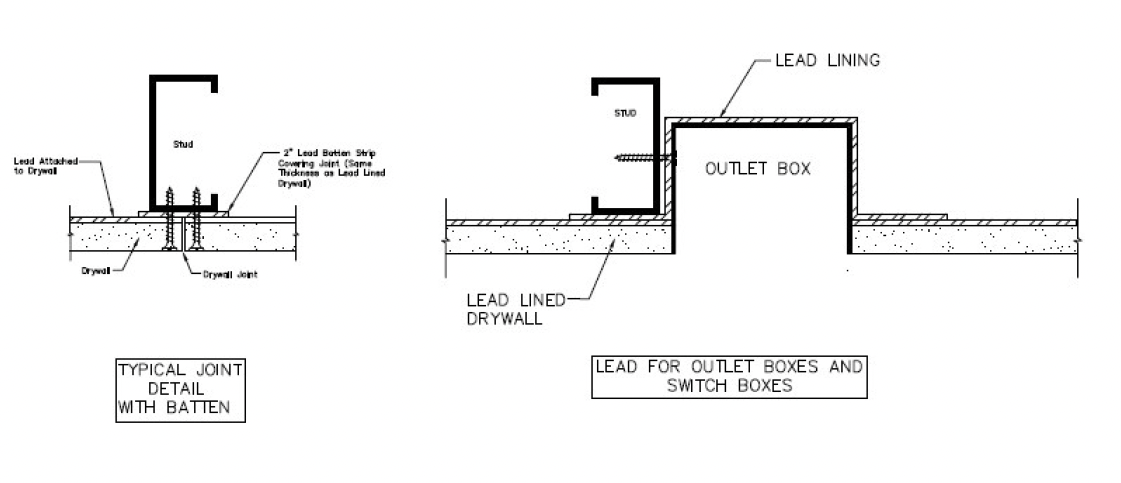

- A minimum lead overlap of one inch is required at all joints and corners.

- Extend lead overhang at least one inch into all frames or openings.

- Fasten lead lined drywall to studs with screws placed a maximum of eight inches on center.

- Install sheet lead over or behind all penetrations, cuts, or punctures to ensure continuity of radiation shielding.

- Please click on Submittal at the top right of this page for more information on installing lead lined drywall.

Dry wall can be taped, floated and finished as required. Protect installed materials from damage by other construction. Have shielding tested by approved personnel. Shielding must comply with all federal and state regulations.

Note: For lead thickness up to 5/64” (5#), a one-inch lead overhang extends off one side of the leaded drywall to serve as a batten strip. If lead thickness exceeds 5/64” (5#), a two-inch lead batten strip will be supplied for each piece of lead lined drywall. Batten strips are required at all drywall joints.

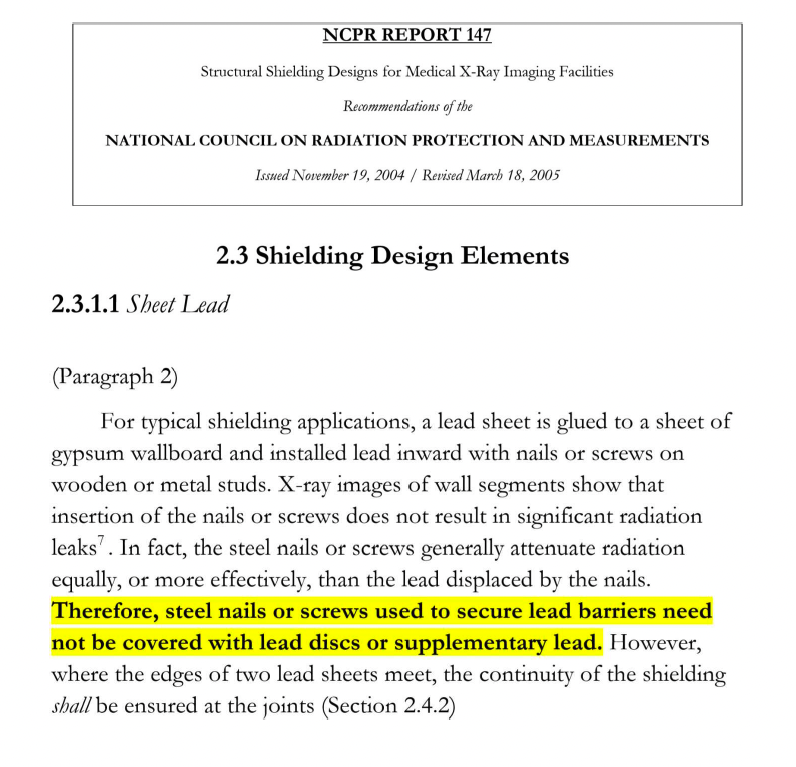

As for fastener, nail and steel screw penetrations, we can provide lead discs, caps or plugs but they are not needed. Please see the section of the National Council on Radiation Protection and Measurements (NCPR) Report on the Submittal concerning these penetrations. If you do miss the stud while using screws to hang the sheetrock, for example, do not back the screw out. Just leave it inserted.

Things to Consider on a Typical Delivery

- Shipped by an LTL carrier

- LTL Driver will NOT unload material

- Truck lift gate not available on the drywall orders

- Heavy skids 4- 10 feet long

- Must be prepared to move material from truck to jobsite (forklift, pallet jack, etc.)

- Call 24hr delivery is available

Typical Details for Lead Lined Drywall:

Sheet Lead

Sheet lead meets or exceeds Federal Specification QQ-L-201 and ASTM B749.

Our sheet lead is ideal for radiation protection as well as sound and water proofing applications. Our lead is 99.5% or more pure and is milled to required specifications. It is available in widths up to eight feet, lengths up to 25 feet, and any required thickness.

Sheet Lead Thickness Chart